Tel/fax.: +7 (7112) 51-36-88, 50-79-09, +7 771 014 92 92

E-mail: info@agrs.kz

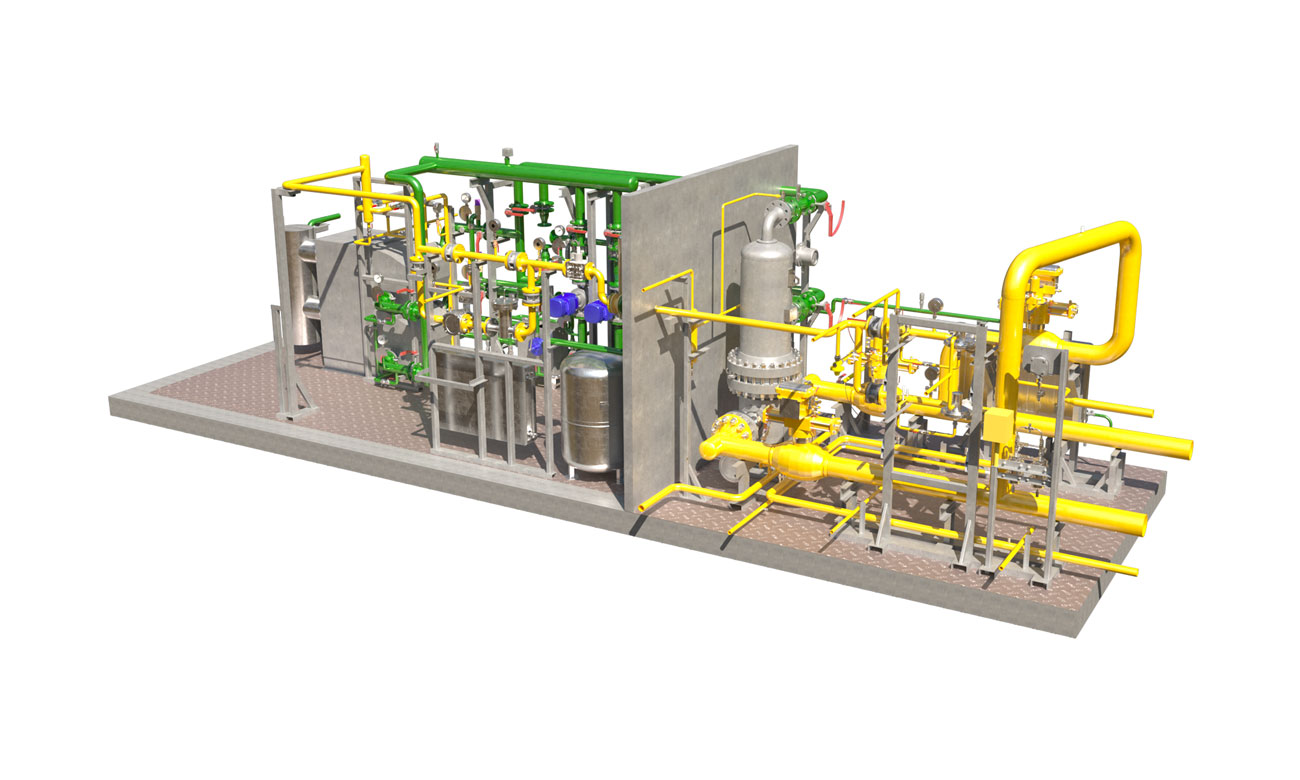

Gas Heating Unit (GHU)

Gas Heating Unit: Application

Gas Heating Unit (GHU) is designed to heat gas to the specified temperature. It can be used at gas distribution and gas consumption systems to prevent hydrate formation during throttling as well as for gas temperature maintenance at the output of GDS, FGTU and other possible facilities.

Operation conditions

GHU is designed for operation in macroclimatic areas with moderate and boreal climate (N and NF) as well in regions with cold climate (F). Climatic GHU modification is chosen depending on construction area and according to requirements. GHU can be operated in regions under magnitude 8.0 on the Richter scale. A designed snow load (200kgf/m2) is to meet the requirements of the V territorial region; and wind load (85kgf/m2) is to meet the requirements of the VII territorial region.

A typical size of the gas heating unit as a part of a gas distribution station is to be determined on the basis of conditions that are necessary for the required gas temperature at the GDS outlet and on the basis of normal operation of station equipment without any ice-coating. If GHU is applied in a heating circuit of the station it is necessary to meter additional heating load.

GHU consists of several skids:

Gas Heating Skid

Gas Heating Skid is designed to heat gas to the specified temperature. Heat exchanges devices with a U-type tube bundles made of stainless steel are applied as heaters. The heat exchanges device is designed to withstand maximum inlet pressure. Protection against tube bundle burst is provided by safety cutout valves.

The skid is equipped by all necessary instrumentation and control devices (pressure and temperature sensors, tube bundle bust detectors) upon the customer’s request.

The gas heating skid can be placed in the unit or in the frame under a roof (in case the heat exchangers dimensions are big).

Coolant Treatment Skid

The coolant treatment skid serves to heat coolant, ensures its circulation, maintains the required excess pressure and regulates a gas flow rate.

The automated control system is based on Siemens Simatic C7-1200, 300 controller and is located in the coolant treatment compartment.

ACS of GTU has the following functions:

- gas contamination signals (СН4) of the coolant treatment unit and gas heating skid;

- gas contamination signals (CO) of the coolant treatment unit with the 1st and 2nd thresholds and stoppage of the boilers when the 2nd gas content threshold is reached;

- stoppage of the boilers operation when both circulation pumps are stopped (reset by the signal from a pressure switch);

- stoppage of boilers operation when a gas pressure to boilers is reduced or increased;

- stoppage of boilers in the absence of flue gases outlet;

- signaling about stop and failure of boilers;

- stoppage alarm and boiler failure alarm;

- pressure increase signaling in the heat exchanger shell (in case there is a break in the tube bundle);

- signaling about the circulation pump problems and automatic transfer to a standby pump;

- control of unauthorized access to the unit;

- fire signaling in the unit and cut-off of gas supply to boilers;

- coolant temperature measurement before and after the boilers;

- gas temperature measurement after heating.

Upon customer’s request an automatic gas temperature maintenance circuit can be installed in the ACS of technical process of GHU.

The technological process flow signals are transmitted to the upper level via Modbus RTU protocol (upon request any other protocol of data transmission or the instrument readings output to the junction box for their further information collection from the automatic control system of the gas distribution system). A set of standard equipment also includes a coolant drain tank, chimneys, gas vent tubes that are mounted on the unit.

Basic GTU features are comparatively inconsiderable overall dimensions taking into account that GTU output level is high, fast and low-cost installation at the site, minimum operating expenses during the period of GTU service life.

GTU Specification

| Parameters | BPG-5 | BPG -10 | BPG-15 | BPG -20 | BPG -30 | BPG -40 | BPG -50 | |

| Operating pressure, MPа | Tube side | 10 | ||||||

| Shell side of heat exchanger | 0,25 | |||||||

| Design pressure, МPa | Tube side | 10 | ||||||

| Shell side of heat exchanger | 10 | |||||||

| Rated capacity, Nm3/hr | 5000 | 10000 | 15000 | 20000 | 30000 | 40000 | 50000 | |

| Heat power*, kW | 22,2-155,4 | 44,5-311 | 66,6-466,3 | 88,8-622 | 133,5-933 | 177,6-1244 | 222,5-1555 | |

| Maximum power consumption, kW | 1,2 | 1,6 | 1,8 | 2,2 | 3,3 | 3,8 | 4,2 | |

| Operating medium | Tube side | Natural gas according to OST 51.40-93 | ||||||

| Shell side | Low freezing coolant (DIXIS, cooling fluid, ethylene glycol solution), water** | |||||||

| Coolant temperature, °С | 80-95 | |||||||

| Fuel gas pressure, kg/cm2/см2 | 0,3-0,7 | |||||||

| Fuel gas consumption, m3 /hr | 2,8-18,3 | 5,7-38,5 | 7,9-49,1 | 9,4 - 78,3 | 16,4- 102,5 | 19,7- 134,5 | 27,4- 162,3 | |

| Overall dimensions, m | 6000x3000x3000 | 8000x3000x3000 | 8700x3000x3000 | |||||

** Not recommended.

&& Final dimensions of the units are determined after receiving customer's technical design basis. Gas heating units with a flow rate more than 50.000 Nm3/h are developed individually, taking into account the requirements of the customer. Zavod Neftegazoborudovanie Ltd. has the opportunity to develop and produce gas heating blocks with a total capacity of up to 1,000,000 Nm3/h.

The compartments ventilation of the required multiplicity is provided by the intake and exhaust grilles installed in the external walls of the unit, as well as deflectors that are located on the roof of the unit.

The lighting under the roof of the gas heating unit is provided by explosion-proof lamps. Lighting in coolant treatment units is provided by fluorescent explosion-proof lamps.

Power is supplied to the GHU from 220V/50Hz or 380V/50Hz industrial network depending on the customer's requirements. Power is supplied through the input cabinet equipped with circuit breakers. The input metering cabinet is installed in the boiler room.

Basic consumers of electric power are the following units of GHU:

- Lightning is divided to an outdoor and indoor lightling of the unit.

- Circulating pupms

- Boilers

- ACS

A reserve power supply can be included in the GHU upon the customer’s request. The redundancy can be made from helium batteries with a voltage converter or from a gasoline or diesel generator.

The arrangement of the gas heating unit allows selecting the GHU upon various requirements for gas pressure and temperature due to the increase the number of heat exchangers in the heating unit and the number and power of the boilers in the boiler room.

The GHU is made so that it can be delivered by any means of transport.